Updated: 2025-09-03

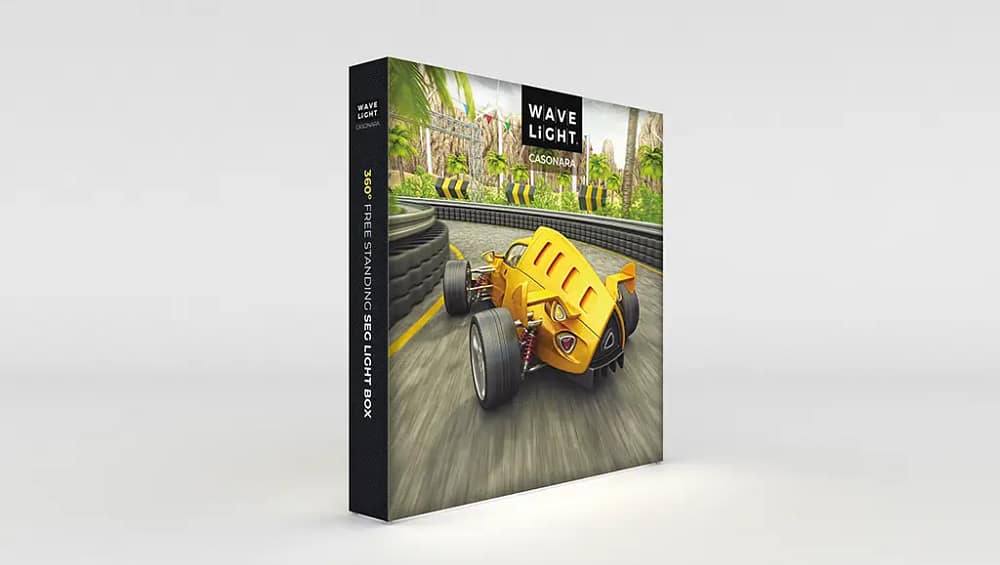

The WaveLight® Casonara Lightbox is engineered to deliver vivid, even backlighting with a fast, repeatable workflow. This article covers portable booth solutions using wavelight® casonara lightbox variations with practical guidance for teams balancing tight schedules, staffing limits, and brand standards.

Kits That Travel

Select case-friendly modules your team can handle without special gear.

Create repeatable pack lists to remove guesswork and reduce stress.

Mix and Match

Blend sizes to frame products, screens, or demo pods and maintain open sightlines.

Keep heights varied to add rhythm and wayfinding inside the booth.

Graphics Strategy

Plan evergreen prints plus seasonal swaps you can rotate city to city.

Localise copy without changing hardware to keep costs controlled.

Operational Wins

Portable designs reduce venue labour and overtime across a full tour.

Standard parts make spares and repairs simple even with mixed crews.

Conclusion: With smart planning and a consistent method, the WaveLight® Casonara Lightbox delivers premium visuals, reliable operation, and smooth logistics across exhibitions, retail activations, and pop-ups.

Learn more about the WaveLight® Casonara Lightbox here.

Additional Tips for Consistent Results

Standardise your build routine across events so every team member follows the same sequence. Keep a laminated checklist in the case that outlines the unpacking order, frame connections, SEG seating pattern, and cable routing. A consistent process reduces errors and protects the longevity of your hardware and graphics.

Capture a quick photo of the finished display during your first setup and store it in the kit. This reference image helps new staff match the approved standard on future builds and keeps colour, alignment, and lighting consistency tight across venues. Small habits like these make a measurable difference to brand quality.

After each event, inspect connectors, wipe the frames with a microfiber cloth, and roll graphics print-to-print to prevent surface scuffs. Proactive care ensures the lightbox continues to present at its best while keeping lifetime ownership costs under control.