Updated: September 11, 2025

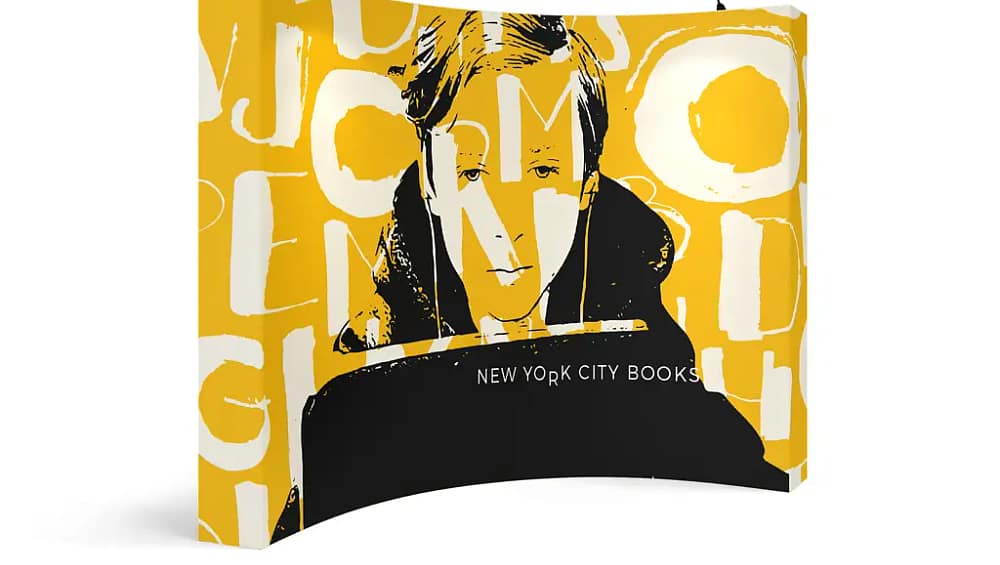

OneFabric Pop-Up Banners combine a quick, tool-free build with a premium fabric finish that looks brilliant in photos and on the show floor.

This article focuses on durable materials that make onefabric pop-up banners last to help you plan, brief your team, and arrive at your next event confident that setup and presentation will be smooth and on-brand.

Aluminium Frame Built for Longevity

The pop-up frame is engineered from lightweight aluminium, chosen for its strength-to-weight ratio and resistance to rust.

Hinged scissor bars open and close repeatedly without bending, even after hundreds of deployments, which keeps the system reliable for frequent exhibitors.

Premium Fabric Graphics with Rich Colour

Printed on tension fabric using dye-sublimation, the graphics deliver deep blacks, vibrant brand colours, and fine detail.

The ink bonds into the fibres, resulting in a soft, glare-free finish that photographs well and resists cracking or peeling over time.

Finish Options and Details That Matter

Edge finishing may be velcro-backed or silicone-edge (SEG), while end caps complete the wrap-around look.

Optional LED lighting highlights the print without adding much heat.

All components pack into a durable case that doubles as a counter when fitted with a graphic wrap.

Sustainability Considerations

Dye-sub fabrics are washable and re-usable, extending lifecycle and lowering waste.

Replacing only the graphic when branding changes reduces cost and environmental impact compared with rigid panels.

Best Practices and Next Steps

Keep messaging concise, pack spare graphics for contingencies, and schedule a five-minute pre-open inspection to ensure perfect tension and alignment.

When your booth looks sharp and setup runs efficiently, staff energy goes into conversations that convert to pipeline.

Explore sizes, graphic options, and accessories for your next activation here: OneFabric Pop-Up Banners.